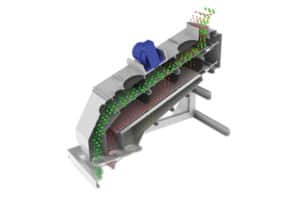

Screening machines are conveyor installations complete with sorting feature. They handle and classify media by means of vibration. As a rule these machines are installed at an angle and feature a circular drive mode. Other drive types can be selected for specific products and depending on the installation conditions. Screening machines can separate different grain sizes simultaneously. The choice of screen lining depends on the task to be performed.

Exemplary type

Circular motion vibrating screen 2.400 x 1.600

Technical Data:

Screen width: 2.400 mm

Screen length: 1.600 mm

Performance: triplane

Drive: eccentric shaft via coupling with DS motor

Shifting: hollow rubber buffers including counter-vibrating frame for vibration isolation

Features

- Compact design

- Only one drive (vibration principle)

- Dust-proof design possible

- High wear-resistance

- High screen throughput up to 500 m3/ h, depending on size

- Alternative option to linear vibratory screen

Benefits

- Low operating costs

- High operational reliability

- Long service life

- Good value for money

- Small footprint

- Excellent separation effect

Technical specs

- Different sizes with screen throughputs up to 500 m3/h

- Drive: one unbalance motor / circular vibration drive

- Optional ball peening attachments for textiles cleaning

- Different screen linings: PU, spring steel wire, VA vanadium steel, slotted hole screens, perforated plates etc.

Application

- Screening

- Sorting

- Protective screening

- Separation

- Drainage