Single-Deck FlipWave™

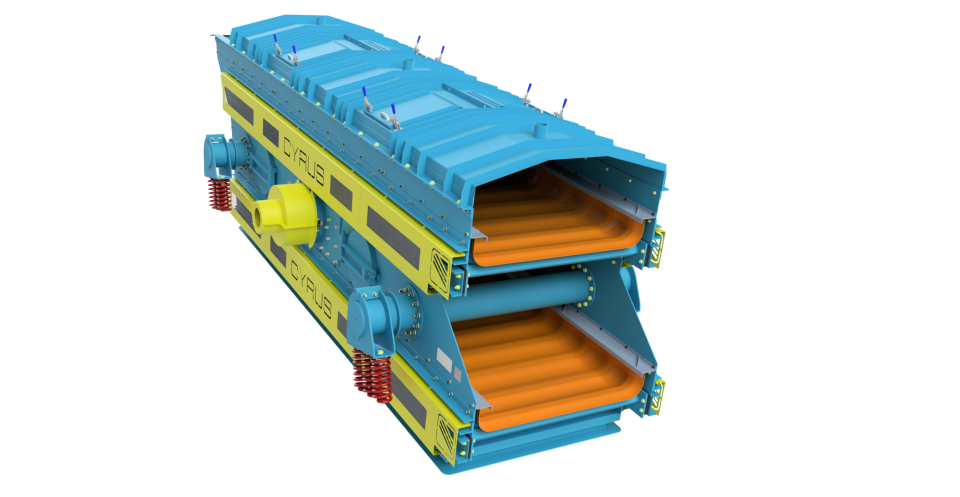

Double-Deck FlipWave™

Streamline Material Throughput

The FlipWave™ screen is CYRUS’ latest screening solution for the recycling industry. Utilizing an innovative, flexible mat deck design, it can handle more materials while minimizing downtime and blockages, allowing you to maintain a steady throughput.

Conventional screens are often limited in what they can screen due to the risk of buildup, reduced efficiency and increased downtime. That’s why the CYRUS flip flop screen was designed to handle tricky materials with high moisture content, like mud, clay, and others.

We provide dual-screen mesh options for a more precise and long-life screening process. The CYRUS Flip-Flow screen transports larger objects over the top protective deck while fines drop down to the lower flexible PU deck to be further sorted, all without blocking the screen.

Additionally, we offer a variety of sieve mats that can easily be swapped out so the screen can handle a diverse range of materials, from C&D to aggregates.

The FlipWave™ uses a standard proprietary motion drive system to generate the primary vibration. The screen includes a sub-resonant frame driven by the main body of the machine, where the screening decks are fixed. This frame generates high-energy forces on the PU panels’ surface, creating a self-cleaning system that is especially suitable for processes with high moisture levels and materials that can blind the screening areas.

Features

- Proprietary Cyrus-Drive Design

- Adjustable Stroke

- Adjustable Angle

- Wide range of sieve mats in various material qualities

- High screening efficiency, reduced screening areas

- Fits a standard European truck for easy transport

Benefits

- Eco-friendly drive and deck design

- Low-maintenance shaft drive design

- Small footprint

- Low operating costs

- Standardized components for easy maintenance

Get a Quote

Optimize your material flow with the FlipWave™ today!